|

Catlypso - Michael & Kelly McFadyen's Sailing Adventures

Latest update 30 April 2015.

This page is about our preparations for when we set sail from Sydney in our yacht, Catlypso and continues from the first part. Click here to read.

26 March 2015

Michael went out to Catlypso today to do a number of things. First, he wanted to see if the wind generator was working. However, the whole time he was on the boat there was only a very slight breeze, not enough to turn the generator.

The second, and most important reason, was to try to fix the engine alarm for the port engine. The alarm is supposed to come on when the key is turned to on and stay on till the engine actually starts. At the same time, the oil pressure light should come on and then go off once the engine is running. He had checked all the manuals and Googled any similar problems and came up with a couple of possibilities for why it was not working.

First he checked the fuse in the instrument panel, but that was okay. Next was to open the engine room and check the oil pressure sender unit. As suspected, the wire was missing off the sender unit. It was found hanging down. It was a simple matter to reconnect it to the pressure unit. It looks like when he removed the oil filter on this side a few weeks back, he hit the wire and pulled it off the sender unit. He will need to be more careful next time.

After this, he decided to check some problems we have had with navigation and anchor lights. The anchor light worked when we left Queensland last year, but gradually over time it has stopped working. At times it was dim or blinking. We suspect that it is a faulty connection or globe, but to check this requires climbing the mast. Of course, we do not want to have to do this, so the best thing is to look at the other options first.

The anchor light is turned on by one of six switches at the helm. What some of the others do has never been worked out, so he also tried to see what they did. First he checked the fuses at the back of the switch panel, all were okay. Next he went into the anchor well. At the back of the well and above the fuel tank is where the cables from the boat enter the mast. There is a bus block here where the cables from the mast are joined together to the power from the boat. Michael checked all four of the cables that come in and exit here. He worked out that one of the switches (labelled Spot) is actually the steaming light. The decklights (two downward pointing lights) are correctly labelled.

The other two connections must be for the navigation lights on the mast and the anchor light, as power comes on when the relevant switch is turned on. Therefore, the problem appears to be at the top of the mast. Looks like Michael will have to climb the mast, bugger. The navigation switch did not do anything, we knew it would not. Why? Because on the trip from Queensland a tri-light fell from the top of the mast and almost hit Kelly. When Michael goes up the mast, he will also need to ascertain why this fell and how it can be reinstalled. All this will probably take a couple of trips up the mast. Michael will draw a diagram of the electrical connection bus and correctly label the steaming light switch.

After this, Michael checked the other navigation lights. Yes, we have two sets, on different switches. The second set is at each bow, simple red and green lights. They used to work but last time we were on the boat at night, Michael noticed that they were no longer functioning. For some reason, these are turned on by a switch at the main electrical panel at the navigation station rather than at the helm.

Neither worked when turned on, so he removed the covers. He discovered that they were LED, but not a globe, instead a board of 12 LEDs soldered to the wires. Straight away for the port one he noticed that the positive wire was not connected. Even when cleaned and touched to the board, the LEDs did not come on. Power is coming in, so it may be the board that is faulty, there is some rust discolouration.

For the starboard one, it was connected but no power was coming in. He pulled the protective cover off the wires coming out of the light and noticed that the spot where the thicker wire from the boat was joined to the wire from the LED board was broken. This LED board did light when powered up, but it was green. This is strange, as the light has a green lens, you would think it would be white so that it was brighter.

Anyway, Michael decided that rather than attempt to repair and put these back in, he would find some white LEDs to replace. As this was the last thing he did on the boat, on the way home he went to an electronics shop and a marine shop and was unsuccessful in finding replacements. Even back home, he was unable to find an exact match on the internet.

In the end, he purchased four (two spares) LED festoons (this is what they call them) that are a little larger at 43 mm x 30 mm than the 36 mm x 30 mm. They will just fit he thinks. The cost was not much, so if they do not, not a lot of dollars (less than $8) have been wasted. He plans to cover the connections with silicone so that they do not corrode like the originals.

31 March 2015

We now have three new scuba tanks for the boat. These are 10.2 litre (85 cubic feet) aluminium tanks. We decided to get some new ones as we do not want to have to use/waste freshwater washing the salt off steel tanks. Michael has now filled them with 34% nitrox. We also got some special diving hangers so can hang up wet suits and BCDs after a dive. Another thing for diving we got was a waterproof strobe for when we do night dives. This will be attached to the anchor or on a drop line from the stern of the boat. We do not intend to do any night dives unless they are straight under Catlypso for safety reasons.

We also now have some additional bottles for our sodastream (think we mentioned we purchased one) so we can have some fizzy water for drinks. Other little things we got were more clothes pegs and some food items that were on special yesterday.

Tonight Michael ordered 110 metres of new 10 mm anchor chain. We do not need this much, but one place we found it was cheaper to buy 110 metres than the 70 or 80 metres we were going to buy elsewhere. Also, this was the only way to get this amount from the place we bought it from in one piece. Michael will collect next week. Now all we have to do is figure out how to get it onto the boat (and the old chain off).

3 and 4 April 2015

On the third Michael went and collected the 110 metres of chain. Talk about heavy, it weighs 251 kg! He borrowed our dive buddy Phil's ute (pickup for our American friends) which meant it could be put into the tray using a forklift. Once he got it home he found it was impossible to move the drum from the ute to the top of the wall that leads to our carport.

When Phil arrived to get his ute (he had Michael's Prado), they both tried to move the drum but it was still too heavy for them. In the end, they pulled the chain out by hand and piled it up on the wall. We think we have worked out how to remove the old chain from the boat and get it back to the car and then take the new chain out to the boat and load into the chain locker. More about this once we do it.

|

| The chain on our driveway as we measure and cut it to size |

The next day we laid out the chain on our driveway and measured it off in 5 metre lengths. We decided to put 70 metres on the boat, replacing the current 60 metres. We cut it into two pieces and stored the 70 metre section till we can remove the old chain and get the new one out. The 40 metres left over we will try to sell on eBay to get back some of our money. The cost of the 110 metres was $1060 (that is $9.64 a metre). If we had bought 70 metres from the only other supplier I found at a reasonable price, it would have cost $1015 anyway. Hopefully if we can sell at about $10 a metre, the new chain will have only cost us $660. As it turns out we sold it for $275 meaning it cost us $785, a saving of $230.

5 April 2015

As normal over Easter, it rained heaps. As such, we ended up cancelling most of the dives we had planned. Today we went out to Catlypso to do a bunch of work. First thing was for Michael to try to complete the servicing of the engines. While he was doing this, Kelly put away a lot of the food and other things Michael had taken out over the past few weeks. She also updated her spreadsheet of the food we have on board (and its storage location).

When we get out there we notice that again we have some water in the starboard hull in the forward berth section. We have been getting water in there over the past month or so. We could not work out where it was coming from as it is seeping in via the floor near the refrigerator. Since we purchased the boat we have occasionally had water in this area, but we thought that it was coming from the fridge or perhaps from overfilling the water tanks on this side.

However, today we realised where the water was coming in. We were outside and noticed that the large window above the galley has separated at the front top section. It seems that it is only held in by the silicone sealant. A section of the window about 350 mm long now has a gap between the glass and the hull. This must have been much smaller before, otherwise we would have noticed it before. This will need to be fixed soon.

Michael first goal was to replace the second, smaller belt on the port engine. This runs the raw sea water pump. He had not been able to replace when he did the other servicing as he was unable to work out how to remove the belt. A look at a manual he found on-line showed that there was a bolt to loosen that let the water pump slide.

He soon works out where this was (it is not visible and has to be done by feel). Before this belt can be removed, the other larger one needs to be taken off the pulleys. This is pretty easy. Once it is free, the old belt is removed and the new one placed on the two pulleys. The water pump is pushed out and tightened and then the alternator pushed out and the larger belt tensioned. The engine is run and all seems okay.

Michael then attacks the starboard engine. He decides to first replace the raw sea water impeller. This has a flat cover which has six bolts holding it in place. The port one was very easy to remove, as there is access to the front of the engine via a door in the back of the shower. However, on this side there is no access from the front, although a door could easily have been installed here.

Michael uses a very small ring spanner and carefully removes the bolts without dropping them into the bilge. Kelly is above him (there is a bit of access to the top of the front of the engine from the double berth) so he passes the bolts and the cover to her.

He removes the o-ring and then attempts to prise the impeller out. This is very hard to do, as there is virtually no room to get any sort of tool into the impeller housing to pull or prise it out. In the end, he uses a combination of some very small screwdrivers to move it out a few millimetres at a time. This damages the impeller which is unfortunate as we planned to keep it as a spare. Finally he gets it out. The new impeller goes in fairly easy and the o-ring, cover and bolts are put back on.

After this, he tries to loosen the arm that holds the raw sea water pump so that the belt can be removed. However, he cannot undo the nut. He actually burrs it a bit, so in the end he sprays it with WD-40 and leaves it for another day, hoping it will free up a bit. He decides not to do the larger belt so he tightens it all back up.

Michael's next task is to replace the cover at the front of the inside of the starboard bow. He removed this hatch last week when trying to work out the reason for the navigation lights not working. This is hard work as it is very hot and humid here and he has trouble finding the holes for the screws. In the end it is all fixed.

The last task was also a major one. As you will have read above, we purchased new chain for the boat as the old chain has a very rusted section, from about 20 to 35 metres that is extremely rusted and not safe. Michael undoes the U-bolt that attaches the chain to the anchor and Kelly ties the anchor to the mast so it will not slip out into the water (it should not anyway as there is another piece of rope attached to the front part).

Michael takes the larger tender around to the front of the boat and then places it in between the hulls and under the trampolines. He has a cardboard box on the floor to protect it. Kelly loosens the anchor winch and then pulls out by hand the chain and drops it though the anchor resting place to Michael who places it in the tender. It takes a while to do this as the chain sometimes jams due to the rust that is falling off the bad section.

Once it is all off, he collects Kelly and Veto and goes back to the boat ramp. Michael moves the Prado onto the ramp as close as he can to the water. Kelly puts the tender straight behind the Prado. She pulls out the chain and Michael takes it and places it on the floor of the station wagon part of the car. It is soon all in the car. We go back out to Catlypso and put the tender back on the davits and Kelly tidies everything else up. We also remove a section of the floor of the upper starboard engine room as this has a broken flush pull (you pull the loop up to lift it out).

|  |

| The old chain, note the very rusted section on left | The small section of floor from the upper engine

room, starboard side with the new flush pull. |

Once we are home, Michael takes the floor section and uses a chisel to make the hole where the flush pull sits a bit bigger and deeper as the new one is a bit different to the old broken one. It does not take long to fix it and put the new one in.

7 April 2015

Michael goes to CBC Bearings at Kingsgrove this morning as he has finally worked out the parts that our Bauer Junior II compressor needs so it can be used on the boat. They have all that he needs, a new pulley of 90 mm diameter, a new bush taper lock for the Honda petrol motor with a 19 mm inner diameter and a new v-belt since the old one is over 13 years old with 1,200 hours use.

The total cost is $62. However, when he gets home and attempts to put the bush taper lock on the Honda motor shaft, he discovers it will not fit. The Bauer manual says that it is 19 mm, but when Michael checks, it appears to be 20 mm. He took the new part back (as well as the Honda motor) and swaps it for a 20 mm one. He tests that it fits on the Honda before he leaves, it does.

Once back home he removes the electric motor, attaches the Honda motor and the new pulley and belt and puts oil and petrol in the motor. It takes a while, but he finally gets the motor to start and it runs, pumping air. He now has all the parts so that the compressor can be used when we are away. Woohoo! He will change it back to electric later in the week (he filled a tank the next day and it seems to be working perfectly).

|  |

| Our Bauer Junior II with the Honda engine filling a tank | The taper lock pulley. You remove the two screws and

then screw one in the hole at the top. This separates the parts. |

While he is out this morning, he also purchases 4 litres of gear oil. This is for the Yanmar S20 sail drives. We do not know when the oil was last changed, so we intend to try to change the oil. However, to do this properly you have to have the boat out of the water. We will not be able to do this.

Instead, we have seen on the internet that you can suck out with an oil pump about one third of the 2.2 litres of oil there is in each drive. We propose to remove one third later this week and put the equivalent amount of new oil in. Then, when up at the Gold Coast in mid-May, remove another one third and put new oil in and then later, remove another third (well almost since we only have 2 litres for each drive. We figure this will basically almost renew the oil.

He also bought some ocky straps as the ones on the boat that stop the TV from moving around when sailing have started to fall apart. When he went food shopping, he purchases a lot of stuff that was on special that we will take with us. He also starts individually bagging some items (sausages for example) and freezing them.

9 April 2015

Michael decided to go out to the boat today to do some more work. It was probably a mistake, as the wind was so strong, the trip out from the boat ramp was very rough and he and Veto got soaked. The wind at nearby Wattamolla hit 43 knots at about the time he went out. The trip is very uncomfortable and once there, he has to change into dry clothes and hang his up to dry. Luckily he has some other clothes there.

Michael's first task is to fix the leaking window on the starboard side. He finds the black silicone and places a large amount along the section that has separated. The problem is that the window is actually straight but the hull curves a little. He finds a section of PVC pipe that is the right length. He uses this to push the window in at the front top, anchoring it on the second stay. This seems to work. He puts a fair bit of silicone on the join and cleans off the excess as best he can. In the wind it is a bit hard as the boat is rocking a lot and things are blowing around. When he leaves three hours later the silicone is drying and the pipe is still in place, so it seems to be working.

|  |

| The window and the PVC pipe holding it in place | The sail drive, yellow round thing is the filler |

He has also taken out the floor section from the upper starboard engine room after his repair. He puts this back in place.

The next thing that he tackles are the sail drives. As mentioned in the last post, we do not know when the oil was last changed in them. You can only change it fully when the boat is out of the water, but you can remove about 700 ml apparently using a pump. He does the port sail drive first. He removes the fill plug which is also the dip stick. The oil is full and fairly black, but not too bad. He gets the engine oil removal pump and pumps out as much oil as he can. He needs to move the hose around a bit to get it down deep into the drive. He removes about 800 ml, so a bit more than what he found on the internet was possible. The sail drive holds 2200 ml (2.2 litres), so he has got just over 1/3 out.

He then puts in 800 ml of new oil. The starboard sail drive is done exactly the same way and he also gets the same amount out. Once we get to the Gold Coast we will remove another 800 ml and put the same amount of new oil in and then repeat again a week or so later. This whole process sounds easy, but it takes well over an hour.

When he went out to the boat he took 20 litres of diesel to top up the tank. He transfers this and we now have 200 litres in the tank, basically a full load. He also puts 10 litres of water in the starboard tank so he can bring back the empty container.

Michael also finds the broken mast navigation light that fell down last June when we were coming back from Queensland. He will take home to check out what needs to be done to fix and reattach. He also took out a bunch more food items and leaves them on the boat.

|

| The controls for the wind generator showing it putting out 6 amps |

As it is so windy, today he gets the chance to check out if the wind generator is actually working. He does not doubt our friend Paul's abilities, he is just making sure that all the parts are working. He turns it on and soon it is running and the ammeter is showing input of between 5 and 10 amps. Brilliant! It is also quieter than it was before, perhaps the new bearings or maybe the fact it is now working under load.

Michael also goes into the upper starboard engine compartment and uses tape to recover the join where the cable from the generator meets the cable to the system. It is now all tidy again.

By now he has had enough, earlier he got hit on the head by the starboard engine compartment door which was blown over by the wind. His head is hard, so that did not hurt much, but he jarred his left shoulder when this happened and it is hurting a little. The run back to the boat ramp with the wind is much better and he and Veto make it without getting wet.

10 April 2015

Today Michael goes out to the boat with the marine trimming people who are redoing the dodger around our helm station. They want us to confirm the location of the small gates we want put in so we can restrict Veto's access to the water from the cockpit. He indicates to them the spot where we believe it will work best. He also checks his window repairs from yesterday and finds that the silicone has set and appears to be holding the glass in place. He removes the PVC pipe.

After this, he drives to Hurstville where he used to work. This is because he is going to buy some meat for our trip. Hurstville has become a centre of Chinese grocery and restaurants for Sydney (outside the CBD) since Hong Kong was handed back to China. The meat here is so much cheaper than anywhere else and it is all great quality. He buys chicken fillet, Scotch fillet, pork and blade steak. He also buys some chicken necks for Veto.

Once home he cuts the meat up into meal sized portions and freezes. We now have enough meat for 32 dinners (almost five weeks), let alone the other meals we will have. At a guess we probably have seven weeks worth of dinners so far.

12 April 2015

We had a bit of a party last night to introduce our house sitters to the neighbours and to also celebrate some other unfriendly neighbours leaving this weekend as they have sold their house. So today was a bit of a late start. We also did not know if we were going to be able to go out there as the forecast was for very strong southerly winds which as you will know from a few days ago can make it a very uncomfortable ride in the dinghy from the ramp.

Anyway, it looks not too bad so after breakfast, we decide to go ahead with the work. As we put the 70 metres of new anchor chain into the back of the Prado, we attach some coloured cable ties to each 10 metre link where we had previously put a white cable tie. This way we can easily tell how much chain we have put out/pulled up.

Once loaded, we head out to Catlypso with the chain and some more cartons of beer. We get to the ramp and it is a bit windier than at home, but not too bad. We put the dinghy in the water, hook up the outboard, load on the beer and motor over. Of course, it is now considerably windier than when we got to the ramp, so we get a little wet, not too bad though.

Once at the boat, Kelly starts to clean the anchor locker. It is extremely dirty, with huge amounts of rust from the old chain. Meanwhile, Michael lowers Thunderbird 2, our larger dinghy, and inflates it (it has a slow leak that we cannot find). He then does a few other chores while Kelly finishes cleaning the locker. It is now a lot windier, at least 20 knots, but we need to complete this task today as Kelly is going into hospital tomorrow so will be out of action for at least a week (she is having half her thyroid removed as it is possibly cancerous).

|  |

| Kelly with her head inside the anchor locker | The almost cleaned anchor locker |

At the ramp, Michael backs the Prado right to the water's edge while Kelly positions Thunderbird 2 behind it. We put a cardboard box on the floor to protect it a bit and then Michael pulls out the chain from the back of the car. This is a lot easier than we thought it would be.

Once loaded, we head back to Catlypso. It is now very windy, at least 25 knots with gusts of 30 knots. In the larger tender it is not too bad, although it is now raining a bit. Kelly gets back on the boat, we start an engine to power the winch and Michael takes Thunderbird 2 around to the front of the boat. As before, he squeezes in between the hulls and Kelly ties him off so the chain is now right under the anchor.

Michael passes up the end of the chain and Kelly puts it though the winch into the locker. She uses a D-shackle to tie a knot in the end so that it cannot come back out the winch if something goes wrong. Once this is done, she uses the winch to pull all the chain back up. Michael does not even need to haul it out of the box, he sits and watches with Veto on his lap. Once it is all up, she reattaches the anchor to the chain and tidies all this up.

The removal of the old chain and installation of the new chain has been a much easier task than we first thought it would be. All that was needed was a little thinking and a good plan.

This is all we are doing today, as the wind and rain has made the other things we wanted to do impossible (putting more silicone on the window and going up the mast). Hopefully Michael will be able to go out on Wednesday and do some other things. He is not going to dive that day in case Kelly needs him at home after she gets back from hospital.

16 April 2015

While Kelly rested up after her successful operation, Michael went out to Catlypso to do some more work. The day was almost perfect, in fact very hot as it turns out, over 30C, not bad for half way through autumn. He also took out some more food items and 40 litres of water.

|  |

| The port dog door supports | A close up of the window repair,

yes, needs tidying up |

Once out there, he notices that the first part of the dog doors has been installed. These are exactly as we asked them to be located. His first task is to add some more silicone to the repaired starboard window. While doing this, a boat goes past well over the 8 knot limit and he loses overboard the old bit of PVC pipe that he was going to use to hold the window in place. As it turns out, he does not need to use it anyway.

He puts extra silicone in place and then also looks at all the other windows. He adds some to a few of them in small sections where the silicone is looking cracked or sad. He will need to tidy this work up later as some silicone is on the glass and deck.

|  |

| The weather station main screen | The outside weather station sensor |

His next task is to install a weather station. At home we have a weather station that records wind, rain and inside and outside temperatures. A couple of years ago the wind vane stopped working so for Christmas, Kelly's sister bought us a new one. This was the cheapest way to get a new wind vane. As such, we had left over lots of bits, so we decided to use them on the boat to give us inside and outside temperatures, humidity and air pressure.

Michael drills some holes above and to the left of the HF radio and puts two screws in place. The main part of the weather station will sit here. Outside in the cockpit he drills two more holes above the starboard speaker. This will hold the outside sensor in place. He puts the batteries in and it soon syncs together. He takes the batteries out and puts the outside sensor inside.

|

A panoramic photo of the watermaker setup inside the hull under the starboard double berth.

Main membrane system at left, pumps and filters middle and freshwater and brine outputs right. |

After making a cup of tea, he decides to get to work on unpickling the watermaker. We have a Spectra Ventura 150 watermaker. We do not know if this actually works as we were told it was "pickled". Pickling is a process where a chemical solution is placed inside the watermaker to protect the valuable membrane which actually does the separating of the saltwater into freshwater and brine. A watermaker needs to be either run creating water or flushed with freshwater each five days so that the membrane is not killed by the microbes in saltwater.

He takes our small netbook into the rear of the starboard hull where the watermaker is located. This is under the double berth. He uses the netbook to consult the manual for the watermaker. He follows the directions to unpickle it. This is basically the same as the start up process.

The process is:

Not all the steps required are actually mentioned in the manual, but the above is what Michael did. After a few minutes of water coming out the sampling hose, it is salt free. Michael gets a water container and collects it. He lets the watermaker run for 10 minutes. The water pressure is not quite the 60 to 90 psi that should be experienced, more like 50 to 60 psi at the most. Looks like we need to check the three filters between the ocean and the watermaker. We also need to perhaps add some air pressure to the accumulator as this may also be causing a problem.

|  |

| The watermaker gauges | The first flow of desalinated water |

After 10 minutes he has about 4.25 litres, that is 25.5 litres per hour (6.9 US gallons/hour). The specifications say that it should make 150 US gallons per day. This works out to be 24 litres per hour, so it seems to be making the right amount, despite the pressure gauge showing lower than it should. He takes this water home to measure it and so Kelly can taste it. She later gives her approval!

He turns off the watermaker and then proceeds to freshwater flush it. This replaces the saltwater in the system with freshwater so that there are no mircobes that can multiply and kill the membrane.

The process is:

As mentioned, this last process needs to be repeated every five days (or less).

We are very happy that the watermaker is working as this means we will not need to carry as much water in our containers and we can also be a bit more liberal in our use. Next time Michael goes out he will check the filters and run again.

After this, Michael checked the raw seawater strainer for the starboard engine and the primary diesel filter as when we were out last Sunday it appeared one or both might be leaking. He had turned off the diesel before the filter and none appears to have leaked since. When he next goes out he will turn this on when he gets on the boat and check an hour or so later. The strainer does not appear to have leaked, but it may when the engine is running.

By now it is very hot, so Michael packs up and heads back home.

Later we go to Aldi to do some more food shopping. We buy lots of stuff that is so much cheaper here than Woolworths and Coles. We get about $110 worth of meat, soups, biscuits and snacks. The next day Kelly makes a cardboard box that is the same size as each of our freezers. We load it up with all the frozen food we have so far purchased. We see that we still have about half a freezer spare, so we can get a few more things.

18 April 2015

Today Michael went diving, so he dropped Kelly at Catlypso on the way out. We took out some more food and other things. As we approach in Le Scat, we notice that the new helm clears are in place (well not quite, the rear one is not there). Also, the completed dog doors are also there. Looks like this is almost complete. Kelly reports that it seems very good work. We later found out that the missing piece was lost overboard and sank! The replacement piece will be done before we leave.

|  |

| The completed port dog door | The starboard dog door folded up |

|  |

| The new helm clears | The new section on the starboard side |

While out there Kelly puts away and catalogs all the food that Michael has taken out recently. She also cleans the compartment under the double berth and also closes the brine discharge thru-hull that Michael forgot to close on Thursday. She also clear the "alleged" vomit smell from the screwdriver case. There was also some water still in the bilge area between the two starboard water tanks that Michael had not been able to remove the other day so she got rid of that as well.

She also did some changes to existing storage areas to accommodate things like our Soda Stream.

20 April 2015

Today Michael was going to go out to the boat to run the watermaker. However, the weather is absolutely atrocious, with winds of over 70 knots (135 km/h) on the coast and heavy rain. In these sorts of conditions it is dangerous to go out to the boat from the boat ramp as it is straight into the wind. Winds of over 25 knots from the south make the bay where we are moored very choppy and in the small dinghy we cop lots of water over the bow etc.

As he ran the watermaker last Thursday, four days ago, it needs to be run again soon so that the membrane is not damaged. The manufacturer says that it needs to be run or freshwater flushed every five days. As the weather is looking terrible for the next three days as well, it is doubtful he will be able to get there before Thursday or even Friday.

He Googled the matter and found that the timefame mentioned by most watermaker manufacturers uses seven days as the recommended maximum, but there are many instances of 10 days or even three weeks being said to be the maximum. He will monitor the weather and if the wind drops enough, he will go out there. Due to the amount of rain we will not be able to make water, but he can flush the system again with freshwater.

Four LEDs that Michael purchased from China arrived in the mail today. These are to replace the LEDs in the navigation lights at the bows. He will need to modify the holders a little, but it should not be too hard. He will reinstall them when he goes out to the boat so long as the weather is okay.

We also got a new Spot GPS device today. We have had a Spot 1 for about six years, it is great. Kelly's Dad Tomas is heading off in July for three months or so on a trip to the Gulf of Carpentaria, the Kimberleys and then back across the centre of Australia by himself. Because he is travelling alone, we decided to give him our old Spot (which he took on another trip around Australia) and we would get a new one.

Michael found on eBay a Spot 2 (an older model but this was new) for $99. It arrived today so Michael set up the new one and then proceeded to change all the messages and contact details so that they will work and make sense. Kelly also set up a new Facebook page for Tomas so that his friends (and family) can see where he is when he camps. We need to get the old Spot off the boat to test that it is all working okay.

21 April 2015

The wild cyclonic weather (category 2) continued all day, with 73 knots again the highest wind nearby. Lots of yachts and power boats are up on the shore north of Sydney and on the harbour. We went down on dusk to have a look at Catlypso from the boat ramp. Yowie Bay was wild, with huge chop coming right down the bay. We could see Catylpso right up the end, she appears okay, but hard to tell from this distance (over 400 metres). So far the AIS has shown that the mooring has not moved at all. Michael will go out as soon as the winds abate, probably not till Thursday morning (today is Tuesday).

23 April 2015

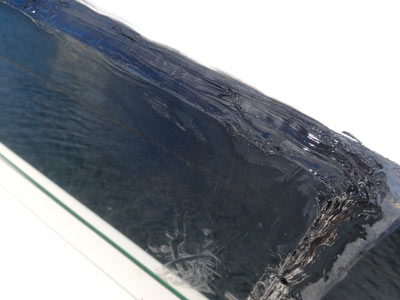

As we guessed, the winds dropped dramatically and today there is virtually no wind at all this morning. Michael leaves home early and is out on Catlypso before 0900. The water in Yowie Bay is filthy, perhaps the dirtiest Michael has ever seen and he has been diving out of here since 1991.

Before getting on board, he circles the boat to check for damage and as far as he can see, there is nothing wrong at all. Once on the boat, he checks the batteries. After almost seven days with virtually no sun, the batteries have dropped from 800 amp hour to 671 a/h. We have a few things running on the boat, mainly the AIS and power for the AM/FM radio. There may also have been some running bilge pumps as you will see later.

Today Michael has a big list of things to do. First off he drops the stern of Thunderbird 2 a bit to let all the water out the bung hole. Even though we leave the bung out when we are not on the boat, it still accumulates a fair bit of water when it rains.

While this is happening, he checks the boat for water ingress. Well, he found some, but not too much. Considering we had about 300 mm (12 inches) of rain since 19 April and 135 km/h plus winds, it is not surprising that some water found its way inside. We end up with water in four spots as far as Michael can see. There is some water where we have had the leak recently, some in the bilge behind this, some in the port forward bilge and water on the navigation desk. The water in the bilge was probably about 600 ml (1 pint) at each location and a few tablespoons on the navigation desk. He soaks this all up and leaves the floor sections off so it can dry. As mentioned, in a couple of spots water may have been pumped out by the bilge pumps.

|  |

| You can see how dirty the water is at the boat ramp | This water came in through the main berth hatch |

Next thing to be looked at is the watermaker. As explained above, the Spectra manual says it needs to be run or freshwater flushed every five days. It is now seven days since it was run, so he freshwater flushes it for about 5 minutes (double what is specified). He cannot run it as the water in Yowie Bay is now brown and mostly fresh due to the rain. He also cleans one of the raw seawater filters but the first one cannot be done as he still cannot remove the lid as the nut holding it on is frozen and the whole bolt and wing nut moves. He puts some more WD40 on it and will try again another day. He also puts some air into the accumulator for the watermaker. This is supposed to have 65 psi but it had perhaps 10 psi.

After this is finished, he adds 20 litres of water to the starboard rear water tank which is the one that the watermaker has been using for the flushing. He also uses the grease gun he has taken out to grease the anchor winch.

Once he has completed this, Michael lowers Thunderbird 2 into the water and pumps it up (it has a slight leak). He loads on board the empty water container and the original prop for Thunderbird 2 and some adjustable spanners. He goes back to the boat ramp and puts the dinghy as far up the ramp as possible.

He puts the water container in the car and grabs 20 litres of petrol out of the car and a siphon hose. He also has 400 ml of outboard oil in a small container. He takes Thunderbird 2's fuel tank out and transfers all the petrol into it and adds the oil. It just fits, meaning there is a bit over 27 litres in it now.

He then removes the prop off the outboard. We purchased an 7 inch prop back in January and swapped it out for the 9 inch one. The aim of this was to get better performance when carrying heavier loads. However, this did not really work as it should, all that happened was that the engine had to work harder and seemed to "slip" when accelerating. He changes the prop back to the 9 inch one as we know that this can get us up on the plane with three people and some gear. The 7 inch will be a spare.

He goes back to Catlypso and puts Thunderbird 2 back on the davits. He unloads some of the additional food and other items he took out and puts some of them away (he leaves the food stuff for Kelly to do as she needs to record where it has been stored).

By now he has been out on the boat for a couple of hours, so he makes a cup of tea. He then decides to reinstall the navigation lights at the bows. To do this he has to solder in new LED modules and attach the light fixtures back onto the bow railing. This requires him to run an extension cord from our berth through the hatch to the trampoline and connect the soldering iron to it. He solders the new LED module to the wires for the port one and then attempts to attach the fixture back to the backing plate but drops the small bolt overboard. Bugger!

He has a look at all the bolts and nuts we have and finds one that will fit. This time he does not drop it and successfully attaches it. He tests the lights and it works. He then tackles the starboard one. This is a bit harder to do as the wires that come out of the hull are not long enough to connect to the LED module. He has to solder on some extra wires to join it all up. In the end he does not fully finish this as one wire will not hold solder due to minor corrosion. He wraps it with electrical tape and puts it all back together and tests. It also works.

He will have to work on this next time out as he needs to be back home by 1300 as there are a couple of people coming to our house.

Of interest, when out on the boat he had the VHF radio on scanning. He hears an Royal Australian Navy warship calling another boat on channel 72. He can only hear one side of the conversation (the Navy) and it seems that the other boat is a fishing vessel, possibly from Indonesia or somewhere else. After asking a lot of questions, the warship advised that they were going to board the fishing vessel. Michael's guess is that the warship was somewhere off the north Western Australian coast, over 4,000 kilometres away.

Back home, our friend Phil comes and they work on fitting our ShippShape cartop tent to his Nissan Patrol. He is going to take it to Cape York (the top of Eastern Australia) in July. We might end up meeting with them somewhere south of Townsville in mid to late August.

The other person coming was to collect the other 40 metres of the chain we purchased. Kelly ended up selling this section via eBay for $275. This means we paid $785 for 70 metres of chain, a saving of $230. He turns up and Michael helps him load it into his ute.

All in all, a good day's work, although two things on his list did not get done.

24 April 2015

Michael went out to the boat again today. Two days of sunny weather with no wind, amazing! He took veto with him this time as he was not going to be there too long. As he approached he noticed that the missing piece of helm clear was in place. You will recall that the people making it lost this piece over the side last week and it sank. It looks like they must have been out there before Michael as there was no dew on it. Looks great!

|

| The helm station from the starboard rear quarter showing the new clears |

Michael took out with him our three new aluminium scuba tanks and some lead diving weights. He put two of these in the bilge at the rear of our cabin and the other one on the starboard side in the same place. He also put the weights there.

Yesterday when he was out at the boat running the watermaker, he took some gaffer tape off the brine outflow hose. This has a Y connection and it looks like this is where the washing machine was attached. Instead of putting a plug in it, they just taped it up. Michael removes this piece of pipe and later takes it to Bunnings (a huge warehouse chain for non-Aussies). He purchases an end cap that can be put on the Y join blocking it off.

|  |

| The two scuba tanks in the port bilge | The tank in the starboard side, we will put an oxygen cylinder here as well |

He also loads some GoogleEarth files of islands on the Great Barrier Reef onto our laptop and reconfigures OpenCPN, one of our navigation programs. He also loads some manuals and diagrams for bits of electronic gear that he had found in the past couple of months. We have basically every manual on our laptops.

While on the boat, Michael uses the new dog doors to keep Veto from straying onto the back steps and the foredeck. Works well.

He also checks all the bilges and no more water has soaked down to them and they are all dry now. After this Michael and Veto head back to the ramp. On the way home, he goes to Whitworths, a marine shop. He buys a net locker (a hanging net to put small things in) and a sail rope bag (also to be used for a similar purpose. He also gets a fishing rod storage rack so we can store our fishing rod and boat hook.

27 April 2015

Michael and Veto go out to the boat again today, this time they also take with them our friend from Melbourne, John. John has not seen Catlypso before today, so it is a chance for him to have a look around. He hopefully will join us in a few months for some sailing and diving on the Great Barrier Reef.

As well as taking out more food items, Michael takes the items he purchased last week (see last paragraph of last day's post). He turns on the fridge and freezers so that they cool down. The batteries are now back up to 100% after last week's atrocious weather.

A major task for today was to fresh water flush the watermaker again. This was quickly done. With John's help, he finally loosens the wing nut on the raw seawater strainer for the watermaker. This means he can clean the strainer of the bits of plant material that is inside. Michael also took out the plug he purchased a few days ago and blocked the Y fitting on the brine outlet hose. No leaks!

He also checks on water leaks as we again had extremely heavy rain on the weekend. There is some more in one spot, but it is not clear if this is seepage from before. Again, we will check this closer in the coming weeks once we are underway.

One of the tasks that Michael did not complete last week was checking the primary diesel filter for the starboard engine. The other week Michael noticed some diesel on the raw seawater strainer which sits under it. Since he cleaned the strainer of the diesel there has been no new diesel on it. However, Michael did turn off the diesel line from the main tank. He starts the engine and runs it for about five minutes and there is still no leaking diesel. We think that perhaps it was diesel spilt when we changed the filters a month or so ago and which has slowly seeped through the sound proofing material and dripped on the strainer. We will keep a close watch on this.

Last night Kelly's Dad, Tomas, brought over the stainless steel compressor housing that he made. This will be used to store the dive compressor inside the saloon of the boat. We designed it so we can slide the compressor into it without needing to lift it over the top as it is fairly heavy. Looks great. Michael will check that the compressor fits tomorrow.

|  |

| The stainless steel compressor housing made by Kelly's Dad Tomas | The opened housing with the compressor inside |

Michael also purchased some straps today that we will use to hold our 20 litre petrol containers in place under the cockpit table. This is the only place we can put them we think. Michael will start transferring frozen and cold food items out to the boat on Wednesday (two days time) as well as diesel and the dive compressor. This will take a while as he will need to use the larger tender off the boat.

28 April 2015

Today Michael could not go out to the boat as he had to go to the Red Cross Blood Bank to donate platlets and plasma. It was his 301st donation and will be the last he can do for six months. As he normally goes every two weeks, the staff there know that we are going sailing and he also wanted to say good-bye to them.

After his donation, he went shopping for some things. The main one was to get wine for Kelly. He ends up getting 8 two litre wine casks, the equivalent of about 20 bottles of wine. Four of these were a cask type we had never seen before, Houghtons White Classic, formerly called White Burgandy. Hope it tastes as nice. We are not taking bottles as they take up too much space and are hard to get rid of once empty.

Michael also purchases another 20 litres of petrol so we now have two 20 litre containers as well as two 5 litre and another 5 litre with 2 stroke fuel. He also gets an end piece to repair a broken boat hook. This is cheap and means we now have two on the boat. He also purchased a net for landing fish.

He gets a couple of other things, including some felt pieces to put on the ends of the compressor container and a freezer pack so we can keep drinks cool if we go ashore for a BBQ or over to another boat.

Once home, Michael converted our Bauer Junior II scuba compressor from electric to petrol. This takes about 90 minutes. He also then checks that it fits in the container. It does, but he has to change the orientation of one of the fill whips so that it fits (he knew he had to do this). He tested it and all works as it should.

He also loads a lot of gear into the Prado as he is going to go out to Catlypso tomorrow, weather permitting.

29 April 2015

The weather this morning is very nice so Michael heads out to Catlypso early as rain and stronger winds are forecast for later on. He loads one 20 litre diesel container, an LPG bottle, the boat hook and fishing net, three Eskys of frozen food and one bag of other food into our small dinghy and motors over. The water in the bay has improved markedly since last week (and even Monday). The wind is fairly strong, probably 15 knots from the south, so he needs to take care to not get wet.

Once on the boat he checks the batteries and finds that it is at 751 amp hours. The sun is out so there are about 10 to 12 amps going in. It also appears that the input from the wind generator is not shown on the main battery panel. The generator is creating between 4 and 8 amps most of the time.

The frozen food is put into the two freezers and some other food into the fridge. He also puts some water, beer and soft drinks in the fridge. The freezers are not half full, but there is more to come. Funnily, when we sailed from Queensland to Sydney last year we had almost full freezers. Just shows the difference that is made by removing all the packaging from some sorts of items.

|  |

The freezers are not even half full,

but there is more to come | Thunderbird 2 loaded with the compressor housing

and other items at the boat ramp |

He then lowers Thunderbird 2 and pumps it up. As normal, it has deflated a bit since we last used it six days ago. He takes the empty Eskys and bags back with him to the ramp. He puts the boat on the ramp and moves the Prado down close to it. The dive compressor container is quite large but not all that heavy. However, it is still awkward to lift and move. He gets it out and puts it in the tender. Also added is another 20 litres of diesel, 20 litres of water, a large dive cylinder filled with 100% oxygen, a small dive pony bottle and another bag of food.

It is a lot drier in the bigger tender so he can travel faster and more directly back to Catlypso. Once there he removes all the smaller items and puts away these things. The oxygen and pony bottles go in with the other scuba tank in the starboard bilge. The two diesel containers and the water container are put in the upper port engine room.

|  |

| The stainless steel compressor housing in the cockpit | The housing in the saloon,

note all the things yet to be put away |

Michael then lifts the compressor housing out of the tender and moves it to the cockpit area. It fits quite nicely here, so we may end up putting it here when we are not transiting long distances. He then moves it to the saloon. We will have to experiment with the best location once we have tidied up the boat. See the photos above.

After this, he decides to try to fix the starboard navigation light. You may recall that he could not solder it dues to water corroding the wires a bit. However, the strong wind means that the soldering iron is not heating up enough to melt the solder, so he has no luck. He decides to use a wire joiner instead for the positive wire. This works. Unfortunately, when he attempts to wrap the wires in some self-amalgamating tape, the positive wire breaks at the solder close to the LED.

This will require a new wire to be soldered in place as there is insufficient length now. This will have to be done tomorrow as the skies to the north are very dark and it looks like it will rain soon. He packs everything up and heads back to the ramp after raising Thunderbird 2 back onto the davits.

On the way home, Michael goes to Whitworths and purchases two pairs of pipe clips, some small hooks and a couple of spare canvas fasteners. He also sees a tube of liquid electrical tape. He tried to buy this yesterday at Bunnings but they did not appear to stock it. This will be very handy for insulating and protecting wires in a couple of spots, so he bought one.

The weather for next Monday (4 May) is looking okay for us. At the moment it is showing southerly winds of 15 knots decreasing as the day goes on. This should give us a good sail to Broken Bay. The next day is looking good for sailing to Port Stephens, 13 knot westerlies.

This afternoon a letter came from Roads and Maritime Services advising that it is okay for us to leave our mooring vacant for six months. If you are absent for more than 28 days you must advise them and get approval. This is to stop people getting a mooring and not using it.

30 April 2015

The weather this morning is not good, it pours rain early and then is constant till just before midday. Michael notices on the rain radar that basically there will be no rain after noon, so he loads up the Prado with two 20 litre containers of diesel, the remaining frozen and cold food, the things he bought yesterday and some diving gear like spare regulator, spares and dive computers.

Sure enough, it clears as he drives to the boat ramp and he and Veto get out to Catlypso without getting wet. There is no wind at all, so he might be able to fix the starboard navigation light. Once on board he puts all the food items into the freezers. There is still a bit of room and the fridge is basically empty. He notices that he forgot to get the two packs of cheese from the fridge at home. The batteries have dropped to 691 amp hours as there has been no sun since yesterday about 2 pm.

He then flushes the watermaker for three minutes. While this is happening, he uses methylated spirits to remove some black marking pen writings that he put on the filters for the watermaker. This is because last year when he labelled it he mistakenly thought it was the raw seawater filter for the starboard engine. He then correctly identifies it with maker pen.

Once the watermaker is finished flushing, he checks the oil in the starboard engine. This is so he can put some diesel containers in there. The next task is to put in place the clips he purchased to hold the second boat hook in place. He decides to put it above the door as this is out of the way. He drills holes in the aluminium frame and screws the clips in place. The boat hook fits perfectly. He decides to wait for Kelly to decide where to put the clips for the fishing catch net and the rope bag. He leaves the battery powered drill on the boat so that we have it for the trip.

The next task is to fix the navigation light. He sets up the extension cord and soldering iron and removes the light cover. He resolders the offending join as well as another one that is not looking good. Once this is complete, he uses the liquid electrical tape and covers each of these joins as well as another one. He doubles up the coverage five minutes later. This stuff seems very good.

He then reattaches the light cover and then uses self amalgamating tape to cover the wires. He checks that the lights are working and finds it is all okay.

The other tasks that need to be done really require assistance, so they will have to wait till Kelly is out on the boat on the weekend.

1 May 2015

Once again there is a lot of rain this morning, 15 mm at least. Michael has been watching the weather radar and believes that there is a window of opportunity where the rain will stop from about 1100 till 1230. At 0935 he and Veto leave home and go to the boat ramp. When they arrive it is still raining but sure enough, it looks like it is clearing.

The rain almost eases so he puts the dinghy in the water and attaches the outboard. He waits till the rain stops before loading the things on board we do not want any of it to get wet. He takes out the seat from the dinghy to give extra space and loads two dive bins full of our dive gear, a weight belt and more weights as well as our four weight pockets. He also takes a bag full of food.

As he arrives at Catlypso his phone rings, it is Eddie our dive buddy. He has rebuilt Michael's dive torch (the battery was failing after 20 minutes) and converted another torch head into a 12 volt cable powered LED. This last one is to plug into a cigarette lighter socket at the helm and be hung over the rear of the boat and down into the water. This is to attach fish as well as light up the area when we do night dives. He arranges to meet him back at the boat ramp in 45 minutes.

The batteries are down to 666 amp hours today, not too bad considering the lack of sunshine and the fact that we have both freezers and fridge running. Around now the sun comes out for a bit and there is also wind. The solar panels are putting in up to 15 amps when there is sun and the wind generator from 2 to 8 amps.

Michael puts one dive bin in the storage area under the double berth in the rear of the starboard hull. He leaves the other one in the saloon till Kelly comes out as he is not sure where to store it (there is room with the other one but he thinks Kelly wants to put something else there.

All the food items are placed with the things he has taken out this week as they will need to be catalogued by Kelly so they can be found again easily. Some other electronic items (cables etc) and stored away as well.

He heads back to the ramp and Eddie arrives just as he does and he gets his refurbished toys.

Today is Kelly's last day at work for six months, so it is a big day for her. She is lucky that they would not let her resign (she works for NSW Fire and Rescue in a very senior role) so she is taking 6 weeks annual leave and the rest as leave without pay. It is great she will have a very good job to go to when she comes back in November.

Heading North to Queensland

Return to Our Yachting Adventures

|

v6.00.307 © 2003-2005

v6.00.307 © 2003-2005